High-Precision Foam Cutting

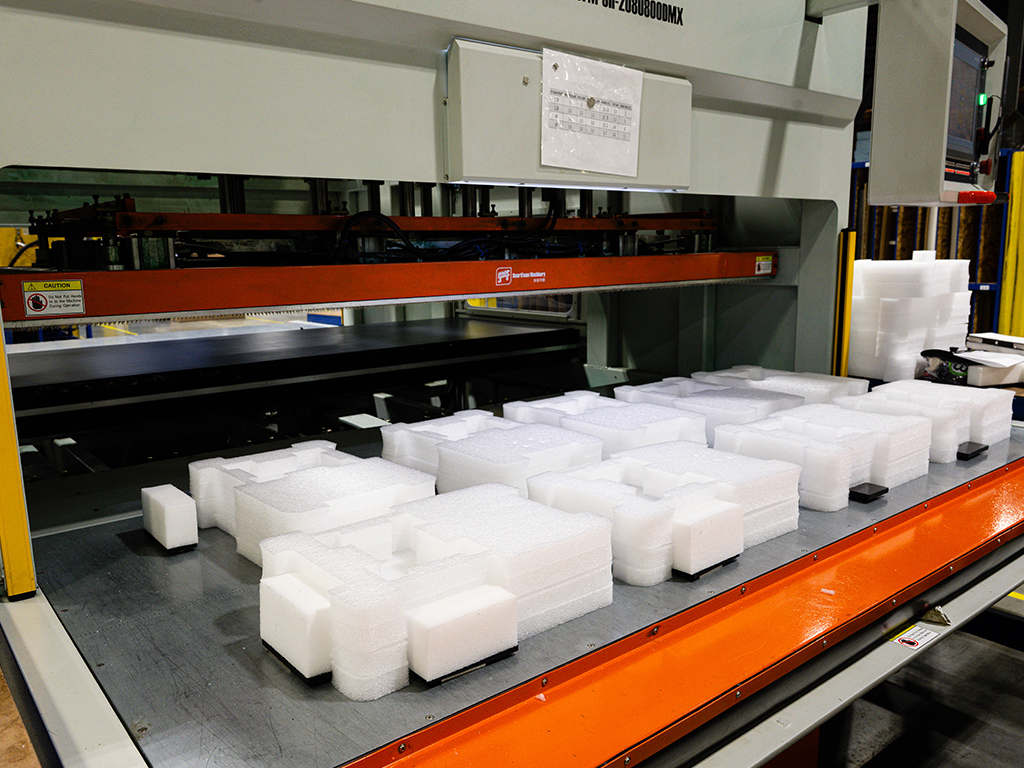

At Unified Global Packaging Group, our foam packaging solutions are designed to protect what matters most, whether it’s sensitive electronics, industrial equipment, or high-value components, we combine decades of hands-on experience with advanced manufacturing to deliver precision, performance, and partnership.

Whether you’re launching a new product or streamlining an existing program, we collaborate with your team to design, prototype, and deliver the right foam solution, on schedule and without surprises.

Custom Foam Solutions Include:

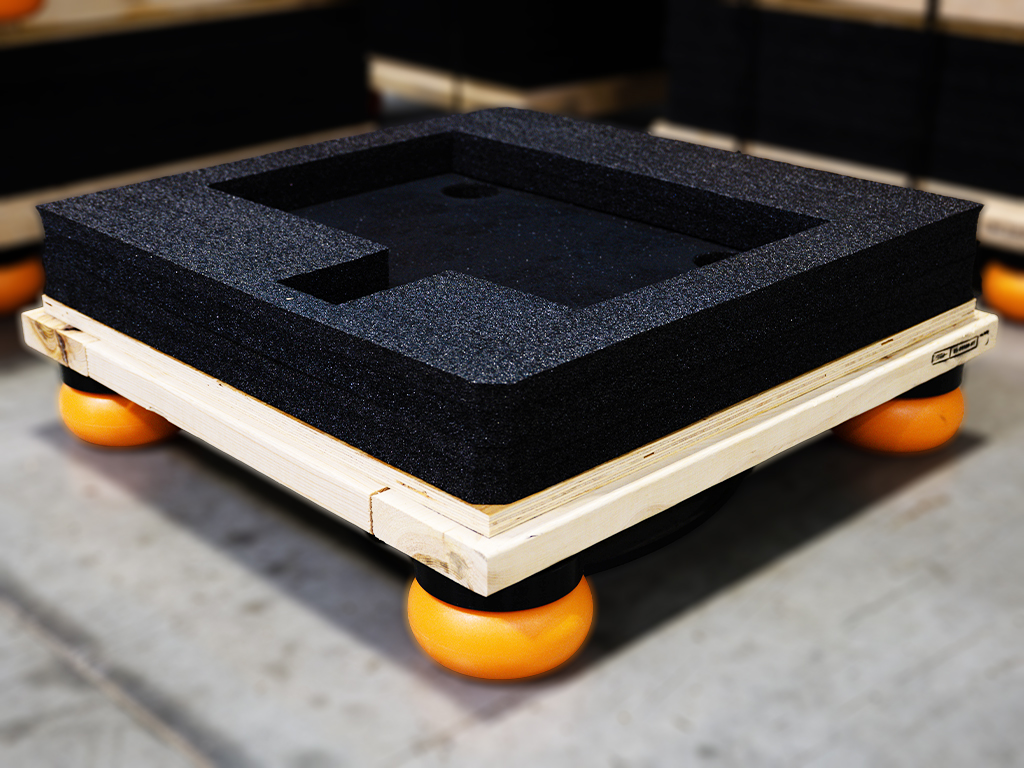

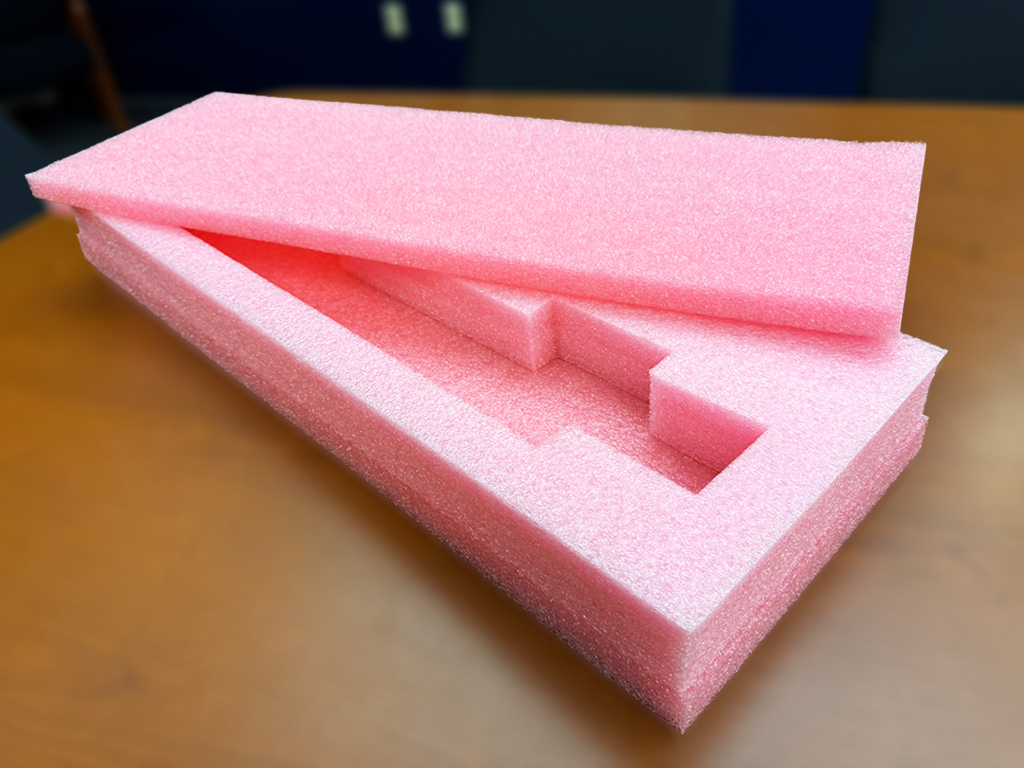

- Foam Assemblies & Material Versatility –Engineered multi-material assemblies combine materials such as Polyethylene (PE), Polyurethane (PU), Expanded Polystyrene (EPS), Expanded Polypropylene (EPP), Anti-Static (AS), and cross-linked foams

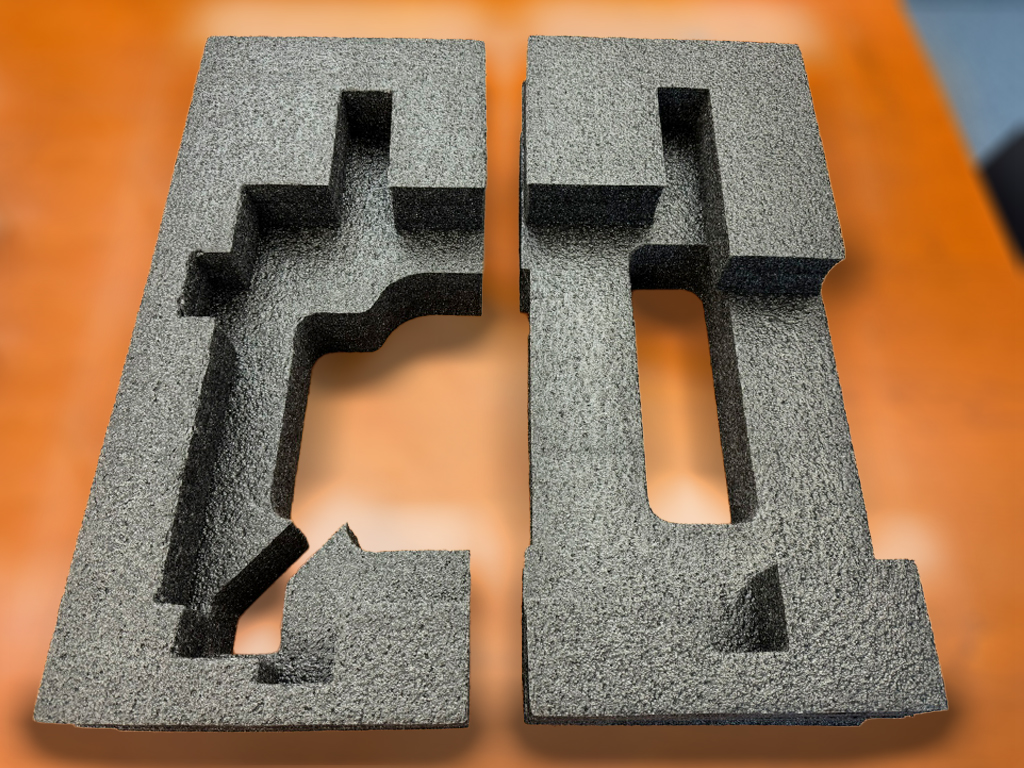

- Protective Foam Case Inserts – Engineered for a precise fit and lasting durability.

- End Caps & Cushion Pallets – Designed to absorb shock, prevent movement and protect corners and edges from impact damage.

- Precision Skiving– Thinned to 1/32” thickness for precise tolerances and optimal performance.

Circular Innovation

- Built-In Efficiency– Smart design strategies that minimize material use and optimize sheet utilization. We focus on creating fit-for-purpose packaging that cuts costs and reduces waste without sacrificing quality or performance.

- In-house Foam Recycling Capabilities – Our pelletizer and densifier transform foam scrap into bricks and pellets for reuse in new foam products.

- Circular Alternatives – Bricks and pellets are returned to our foam supplier and reprocessed into 100%[1] post-industrial recycled content (PIR) PE Black RENEW Foam[2] (excl. additives & chemicals), a high-performance, low-carbon solution (LCA available upon request)[3] to virgin foam.

[1] 100% PIR refers only to the recycled foam content and excludes additives and chemicals.

[2] UGPG2 is currently working with Pregis to get this process third-party verified.

[3] This LCA report was generated by Pregis using ISO-certified EcoImpact COMPASS by Trayak and is based a blend of product-specific operational data, regionally collected data, and industry-average datasets. The COMPASS methodology follows ISO 14040 principles, which require third-party critical review before using LCA results for public comparative claims.